The spur from the

Pennsylvania Railroad to The Upjohn Company manufacturing

complex in Portage was installed early in the construction of

the site in the late 1940s.

Most of the construction materials and

steelwork were brought in by railroad. From movies taken of the

construction, it appears that the first Upjohn switcher, a new GE

25-ton unit, did not show up on site until the initial

construction was well under way. Before then, railroad cars were moved

around by a bulldozer so construction materials could be

unloaded at the right place.

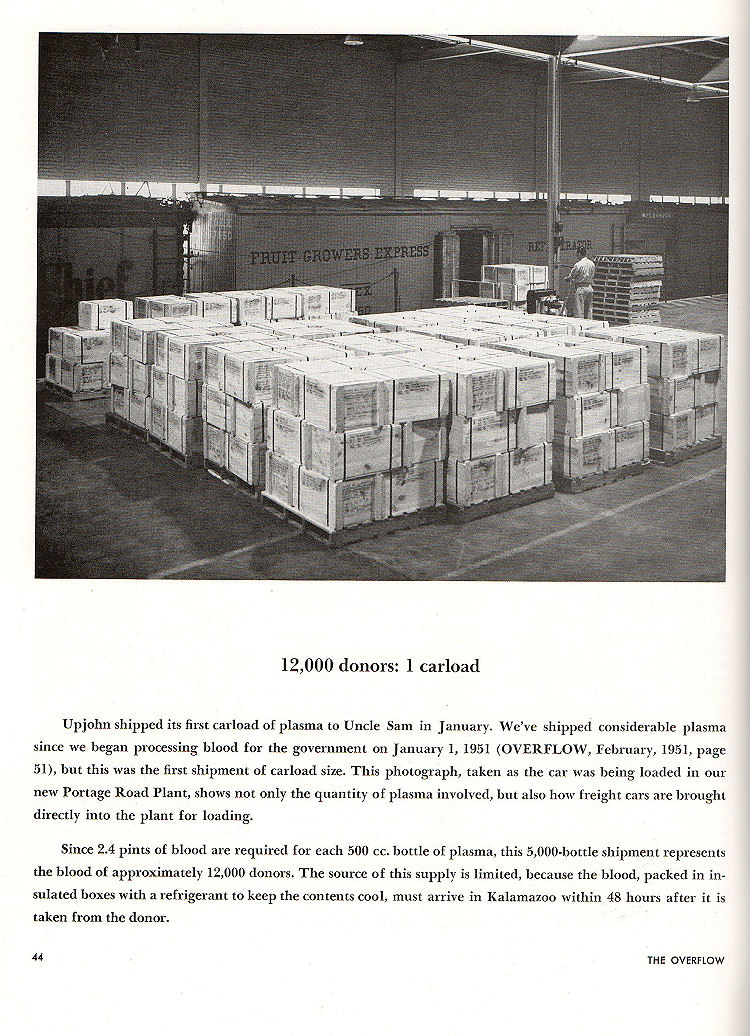

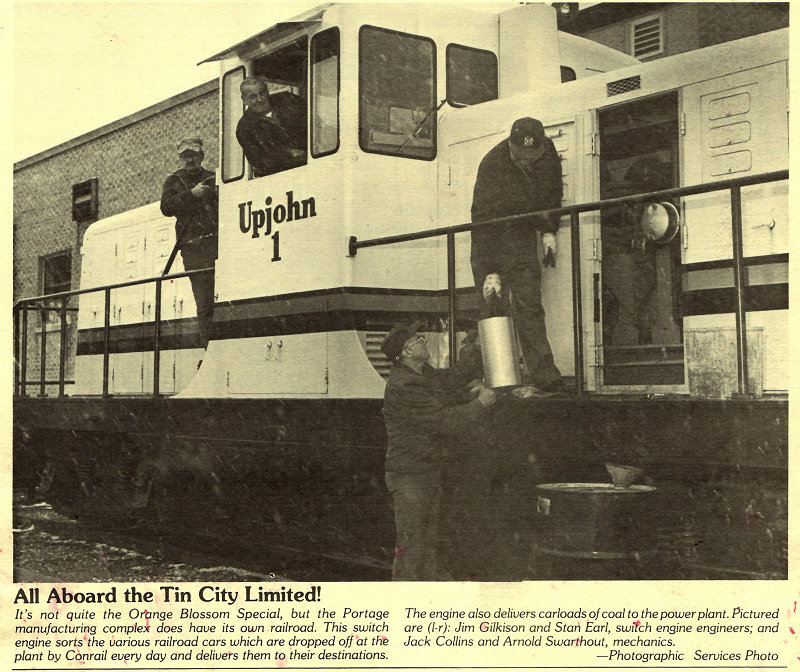

At the start of manufacturing,

91% of inbound shipping, not including coal, was by rail. This

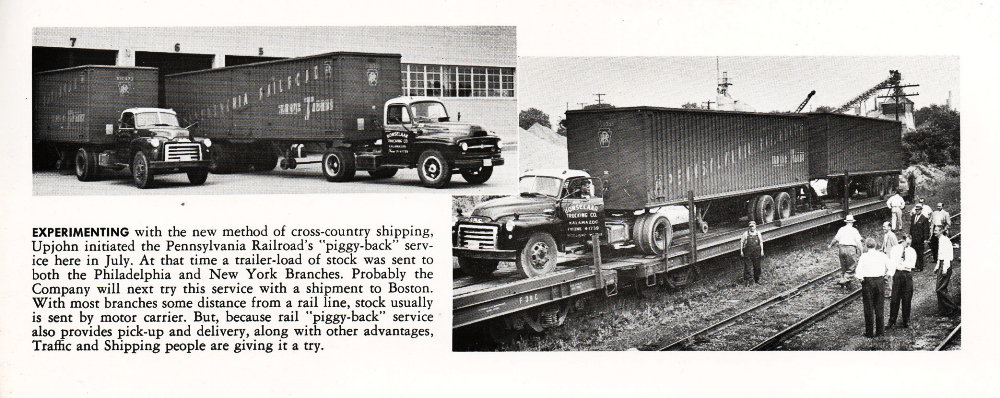

means that practically everything came in by rail. Boxcars and

TOFC were used to send out Upjohn finished products to five

distribution centers - New York, Dallas, Los Angeles, San

Francisco and Portland. However, in 1973 trucking took over all

ground shipping to the distribution centers. The rail spur

continued to handle inbound materials, solvents and coal. By

1984 the percentage of inbound shipping delivered by rail was

still 75% when including coal. The amount of coal delivered at

that time was 165,000 tons a year. It was stockpiled at the rear

of the facility and taken to the power-house every day using a

small fleet of Upjohn-owned open hoppers.

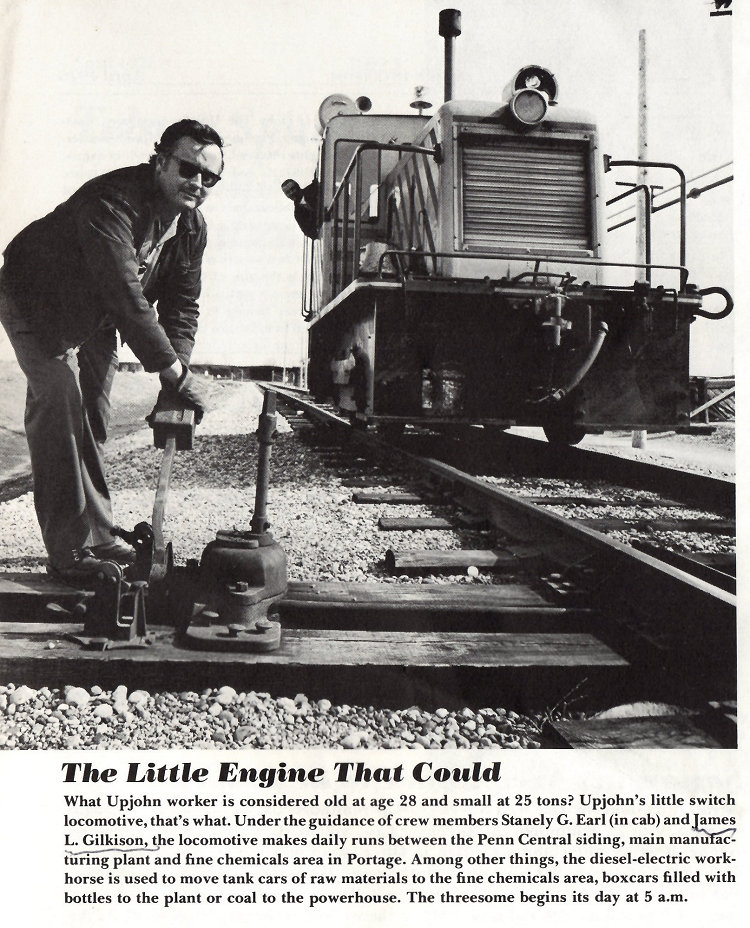

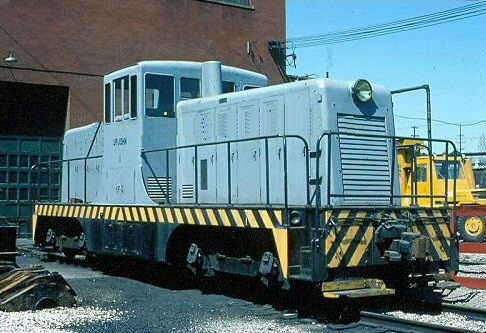

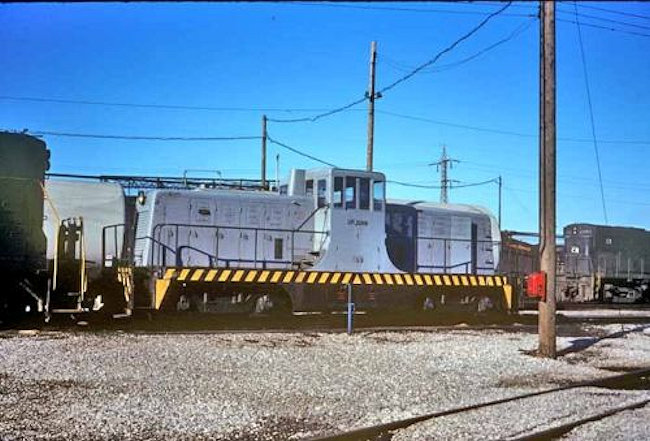

When the

first switcher became too small for all the work, a more

powerful 44-ton GE machine, previously used by the U.S. Navy,

took over in 1977. Photos of both are shown below. The original locomotive

was stored in the Building 41 south-east warehouse bay for many years, finally being

transferred to a Monsanto facility in Missouri in the late

1990's. The second Upjohn switcher was replaced in the early

2000's by a larger Alco unit. This switcher is still used daily

at Pfizer in 2025.